Download |

Download |

Download |

Download |

Download |

Download |

Download |

SB Broneske combines heat resistance and structure borne noise reduction

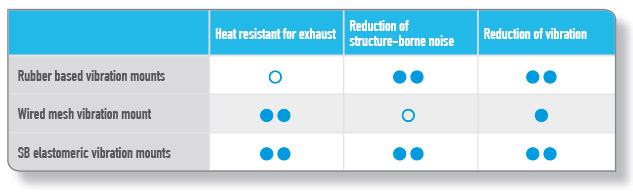

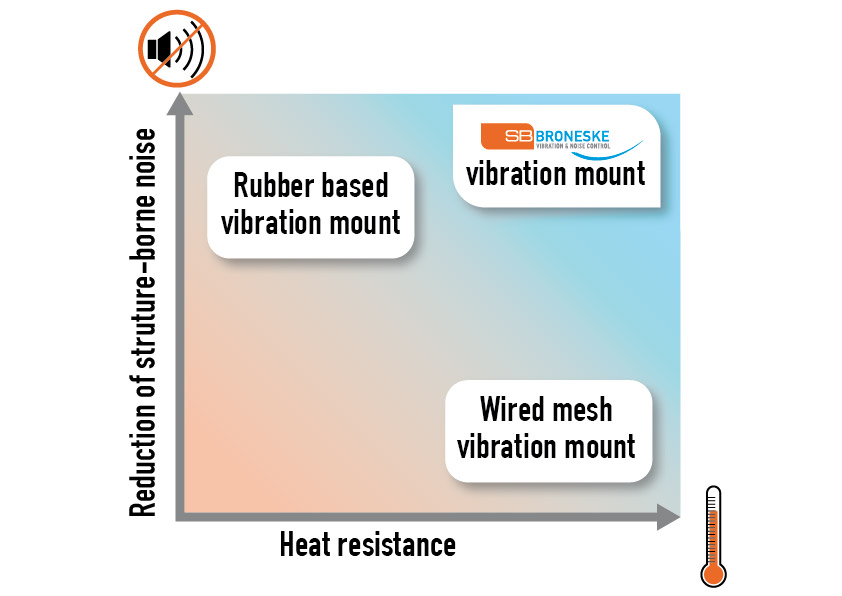

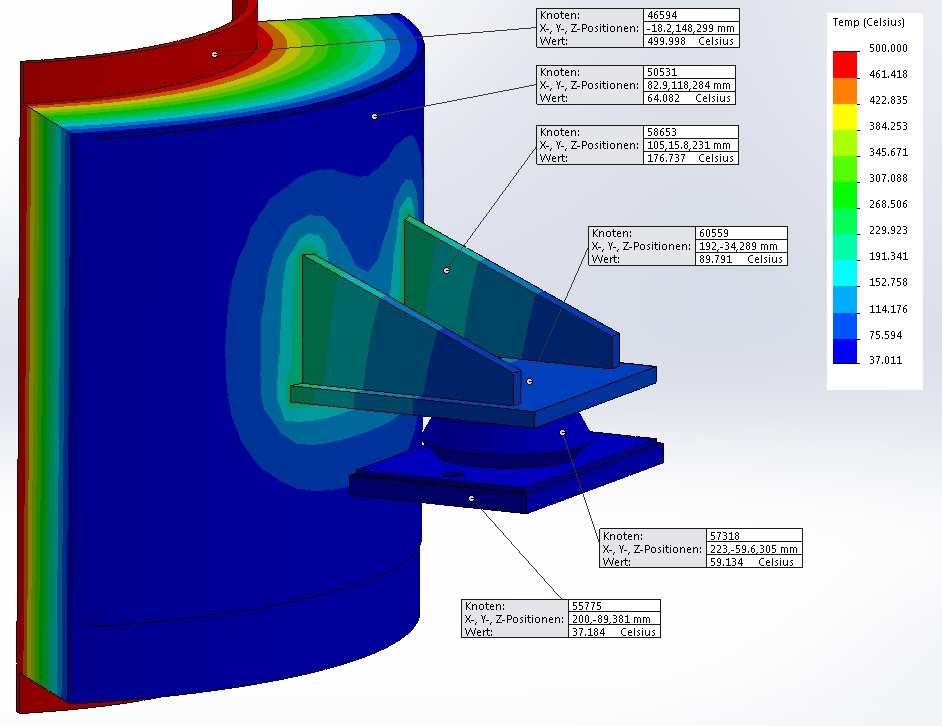

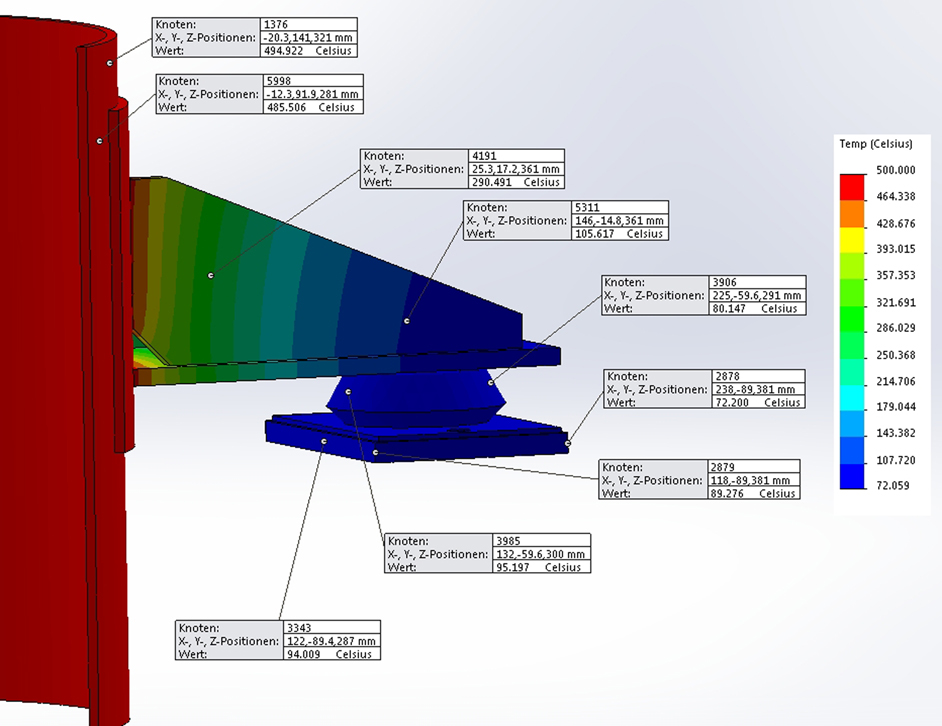

The SB Broneske vibration mounts fix points are specially designed for the exhaust pipe system of ships (maritime environment). We produce our vibration mounts fix points with a special high effective heat resistant elastomer. Because of this they are shear-proof, fire-proof, heat resistant up to 300° Celsius and very effective reducing vibrations and structure-borne noise.

Elastomeric vibration mount with natural rubber are only heat resistant up to 80°C. If the temperature at the surface of the insulation is usually 150°C, the elastomeric rubber vibration mounts with a limit of 80°C would melt. Some other suppliers use ceramic insulation washers. But this does not really help. In difficult installation places, the natural rubber vibration fix points melt.

|

|

Rubber vibration mount: The change of body sound from pipe [steel (5000 m/s)] to rubber [vibration mount (90 m/s)] to deck [steel (5000 m/s)] is very effective.

Reduction of the body sound up to 99%.

Rain caps are absolutely necessary for the exhaust pipe of each ship. They keep the water away from the funnel case. At the same time our rain caps allow the warm air of the engine room to escape upwards. SB Broneske provides rain caps for vertical and in addition for horizontal exhaust pipes. Both rain caps are specially designed according to their requirements and to minimize the structure-borne noise at the funnel top.

Only rain caps for horizontal installation effectively protect the funnel against rain and splash water. A horizontal exhaust pipe in the funnel case requires a special design of a rain cap.

SB Broneske rain caps are available from DN40 to DN3200. Thus, our rain caps cover the complete spectrum of exhaust pipes.

Please contact our experts for detailled information.

The first high-pressure SCR for two-stroke engines, which meet IMO's Tier III regulations for engine emissions of nitrogen oxide (NOx), has passed factory acceptance test in January 2015 and entered into service in August the same year. In the course of this project SB Broneske supplied Winterthur Gas & Diesel Ltd. (WinGD) with vibration mounts and expansion bellows for very heavy loads. WinGD is one of the leading developers of two-stroke low speed gas and diesel engines which are sold under the Wärtsilä brand name.

SCR (Selective Catalytic Reduction) systems have been developed for cleaning exhaust gases of marine diesel. The combustion process of the air-diesel mixture cause exhaust. Exhaust fumes contain some harmless substances such as water vapor, carbon dioxide and nitrogen. They also contain carbon monoxide, hydrocarbons and nitrogen oxides (NOx). However, these latter exhaust fumes are very dangerous to humans and nature. The SCR system acts as a crucial part in the purification of diesel exhaust gases. In this system injecting urea dissolutions into the exhaust pipe reduces nitrogen oxides (NOx).

SB Broneske offers elastic support for SCR systems with special vibration mounts. For square systems we choose four fix points and four anchorage points for an optimal elastic support. However, it must be ensured that the lower fix points have uniform spring deflections so that the structure-borne noise is evenly reduced and vibrations are avoided.

For more than 40 years now, SB Broneske has been providing unique vibration mounts for the elastic support for exhaust pipe systems. These vibration mounts have to meet strong requirements: They have to be shear proof so that in case of fire they keep the exhaust pipe in position. During storms they also have to withstand dynamic movements. It is very important that all supply circuits are strictly separated from and to the SCR in order to avoid impact borne sound bridges.

Since manufacturing engines with a high-pressure SCR system, reliable and functional elastic supports are required for the innovative exhaust gas cleaning systems. Every exhaust gas cleaning system has its unique features and SB Broneske‘s goal is to provide their customers with the most efficient and reliable elastic support.

Please follow this link to read the press release of WinGD about the first Wärtsilä two-stroke engine with Tier III compliant high pressure SCR.

Exhaust gas flaps are used to cover the vertical open ends of the exhaust pipe system. The special stainless steel gas flap protects the engine and the exhaust pipe system against corrosive influences of rain and snow.

Our exhaust gas flaps adjust to the operating status of the engine: They open or close while the engine starts or turns down.

The exhaust gas flaps are available from DN32 to DN3500. SB Broneske is also able to manufacture customized exhaust gas flaps. Additional sizes and materials are available on request.

Please contact our experts for detailled information.

We use cookies to give you the best possible service. You can choose which cookies you would like us to set. Please note that depending on your settings, not all features of the page may be available. Further information can be found in our privacy policy.