Current Situation

The emission caused by shipping is increasingly becoming more of a burden on the environment especially for coastal regions. For this reason, the International Maritime Organization (IMO) already signed an international agreement for marine protection named MARPOL (from marine pollution) in 1973. This contract had been complemented in1978. A step-by-step reduction of the emissions' appointments is regulated in the Annex VI (MARPOL 73/78).

Furthermore the IMO specifies the so-called Emission Control Areas (ECA) for which very tight emission limits were applied. The Emission Control Areas (ECA) are areas where noxious substances are especially defective for humans and the environment.

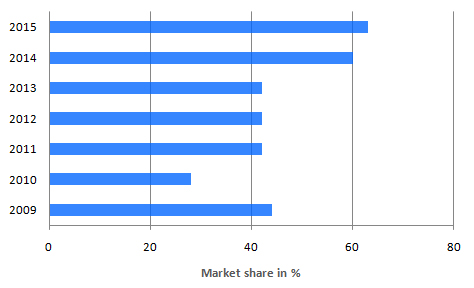

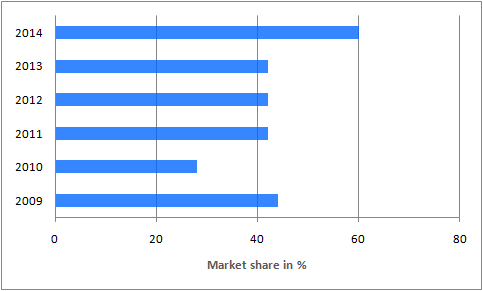

According to the agreement with effect from 1st January 2015, only 0.1 % sulfur is allowed to be present in the fuel when willing to navigate through such an ECA. This value is 90% less than the present maximum permissible value. At the moment the achievement of this value is only possible with distillates, but they are too expensive. However, upgrading of emission control systems represents a commercially sustainable solution. This upgrading of vessels with such systems is also called "Retrofit".

Sustainable Solutions

Besides the numerous internal engine measures to reduce the emissions, the trend is towards external engine measures.The so-called exhaust after-treatment systems are one of the most important groups of the external engine measures. The following systems have been established in shipping:

- Diesel oxidation catalyst (DOC) is used to reduce particles, carbon monoxide and hydrogen

- Selective catalytic reduction (SCR) mainly reduces nitrogen oxides by a selective chemical reaction

- Particulate filter (PF) are used to reduce soot particles arising during the combustion

- Flue-gas scrubbing is a complex but effective method which mainly is used for desulfurization and denitrification of the exhaust gas

- Electrostatic precipitator (ESP) is a system for removing particles by using the force of an induced electrostatic charge

How SB Broneske can support you

Retrofit measures are often costly and time-consuming for ship owners. Therefore the profitability of retrofitting does highly depend on the longevity of the system. The application of SB Broneske elastic supports reduces the vibrations and thus not only the structure borne noise, but significantly contributes to a longer lifetime of the system.

During more than 40 years of existence, SB Broneske has already gained enormous experience in the field of retrofitting and reconstruction of exhaust systems. Many standard products of SB Broneske have been specifically developed for retrofit measures and modified accordingly.

Our specially developed vibration mounts for heavy loads are able to bear up to 25 tons per vibration mount, so even larger systems such as dry- or wet-scrubbers can be supported effortlessly.