The first step in the way to a reliable exhaust pipe system is a drawing (2-D) or model (3-D) of the exhaust pipe arrangement. From the given specifications, our engineers derive the technical configuration of the elastic support system in close collaboration with the shipyard's technical staff. This layout proposal also plays an important role during the installation phase as all devices are already drawn into the pipe arrangement and installation engineers can easily identify the different installation positions and the corresponding equipment.

Knowing where the individual elastic parts need to be placed does not necessarily make a reliable exhaust pipe system. In the second step of our technical support we carry out the necessary calculations with our very own SB Broneske software. As a result it not only calculates the reduction of structure-borne noise for each position in the layout proposal, moreover, it helps us to identify which one of the SB Broneske mechanical parts is the best solution for it.

Almost every exhaust pipe system is a unique and we want its design and subsequent installation to run as smoothly as possible. Therefore we have developed a so-called Design Office Check List. This check list contains many important aspects which are not solely in our hands, and should be clarified before placing a final order, in order to prevent subsequent complications.

SB Broneske's goal is to provide its customers with the most efficient and reliable elastic exhaust support system. Every ship has its unique features and it is of utmost importance to attend to these very special characteristics and not provide an off-the-shelf product.

SB Broneske has been presenting the world’s first flexible deck and bulkhead penetration for exhaust pipe systems. It is fire- and water-proof and does not transfer any vibration into the ship’s structure. It is especially popular with all kinds of passanger vessels and luxury yachts. We hope you got detailled informationabout our world exclusive penetration, our new products and services.

Our fantastic exhibition team can look back on many interesting and exciting days and is looking forward to welcome you to our booth at the SMM 2016. We look forward to a successful cooperation with you. We were most impressed by the crowd at our booth and hope that all our visitors had a good time at the fair and were able leave with many impressions, suggestions and a lot of information. Thank you for visiting us at the world’s leading maritime trade fair in Hamburg.

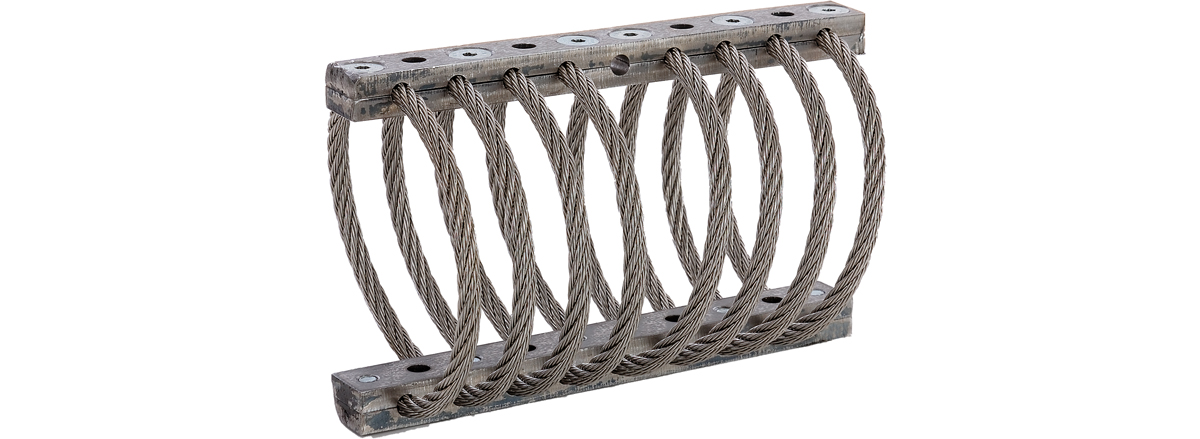

- Load: up to 310 daN (axial (-))

- Natural frequency: 6 - 10 Hz

- Material wire: Stainless steel

- Material bars: Galvanized steel, Stainless steel, Aluminium

- Temperature range: -240°C up to 370°C

- Temperature range: -400°F up to 700°F

- Additional sizes and materials available on request.

For more information please download the Product Data Sheet...

He was selected as a new board member for the Working Group on 08.09.2014 in Hamburg.

The entire members list please find here...

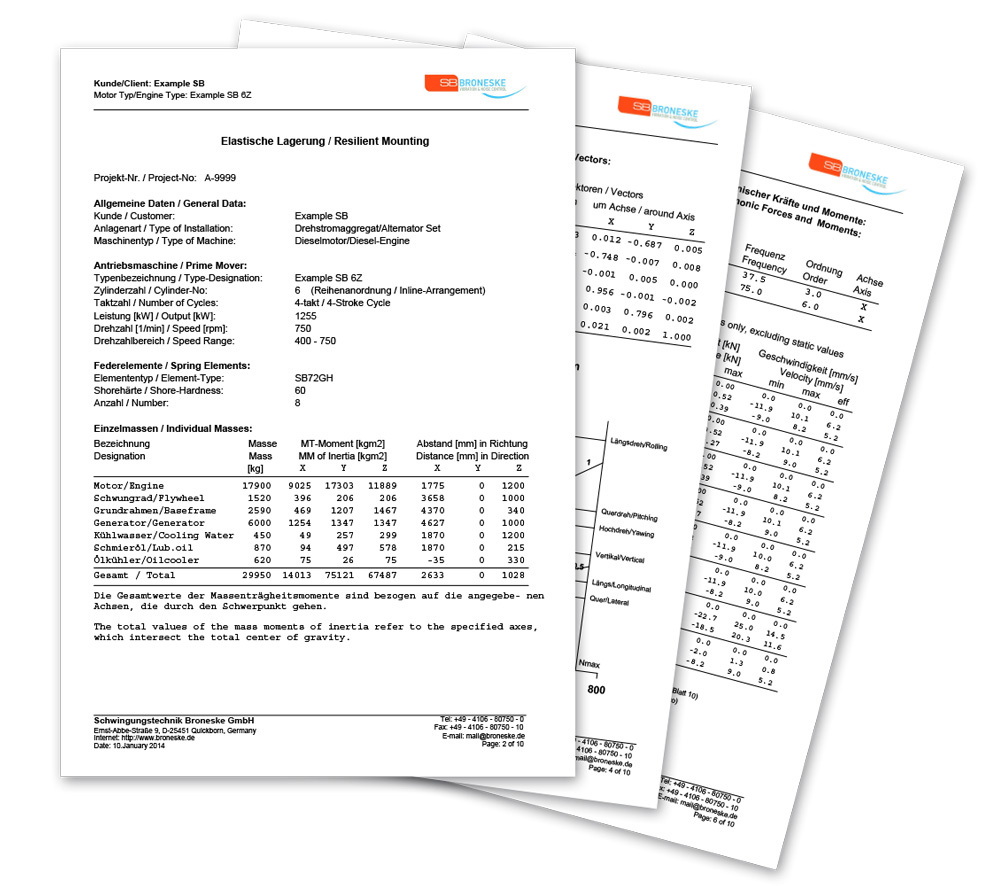

SB Broneske offers an advanced and free of charge vibration analysis for engines - using a specially developed program. The calculation includes the following points:

- overview of engine data

- positioning of vibration mounts

- natural frequencies and vectors

- critical speed diagram

- static deflection under the dead weight

- displacements, forces and velocities caused by free harmonic forces and moments

- vibrational movements caused by free forces and moments as graphics

- vibration isolatio (V D)

- displacements caused by the ship's motion ( rolling / pitching)

We use cookies to give you the best possible service. You can choose which cookies you would like us to set. Please note that depending on your settings, not all features of the page may be available. Further information can be found in our privacy policy.